By utilising the latest in industry design skills and technologies, we strive to offer our customers peace of mind by way of design analysis, quick processing times and cost-effective moulding solutions.

In offering an ISO 9001:2015 manufacturing standard, our team of highly experienced in-house staff and dedicated network of toolmakers are on hand to offer our customers the relevant direction, recommendations and full project management services.

Send us your 3D file: /stp / .igs / .x_t / .x_d / stl

We will work directly with your existing / native CAD data and provide a full project management servivce.

We can help you create your project

Our expert team can provide the relevant technical advice and guidance.

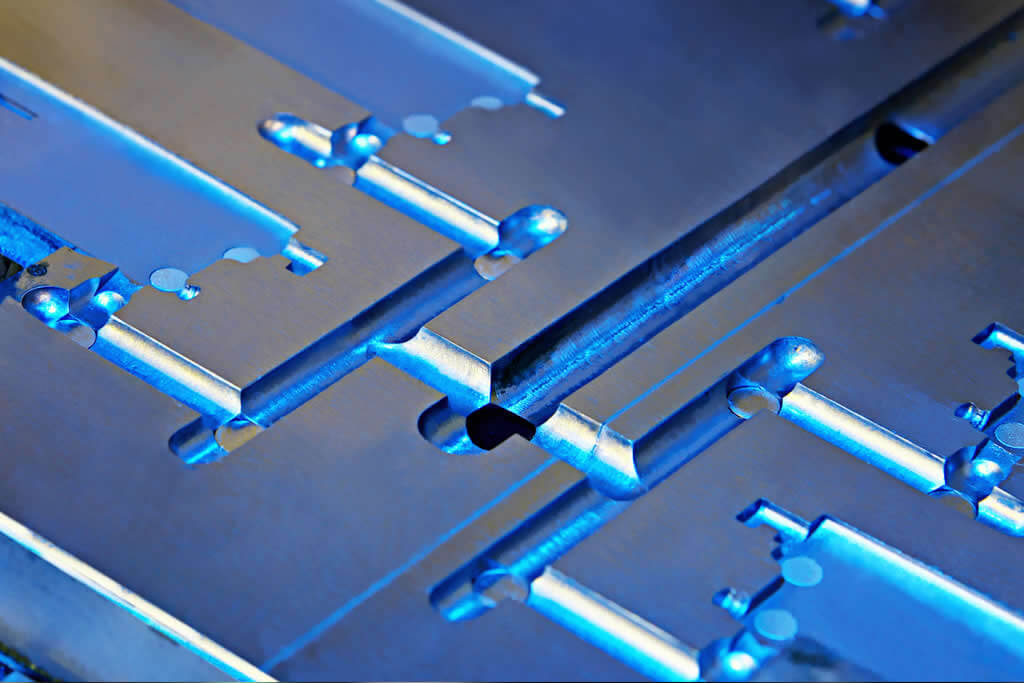

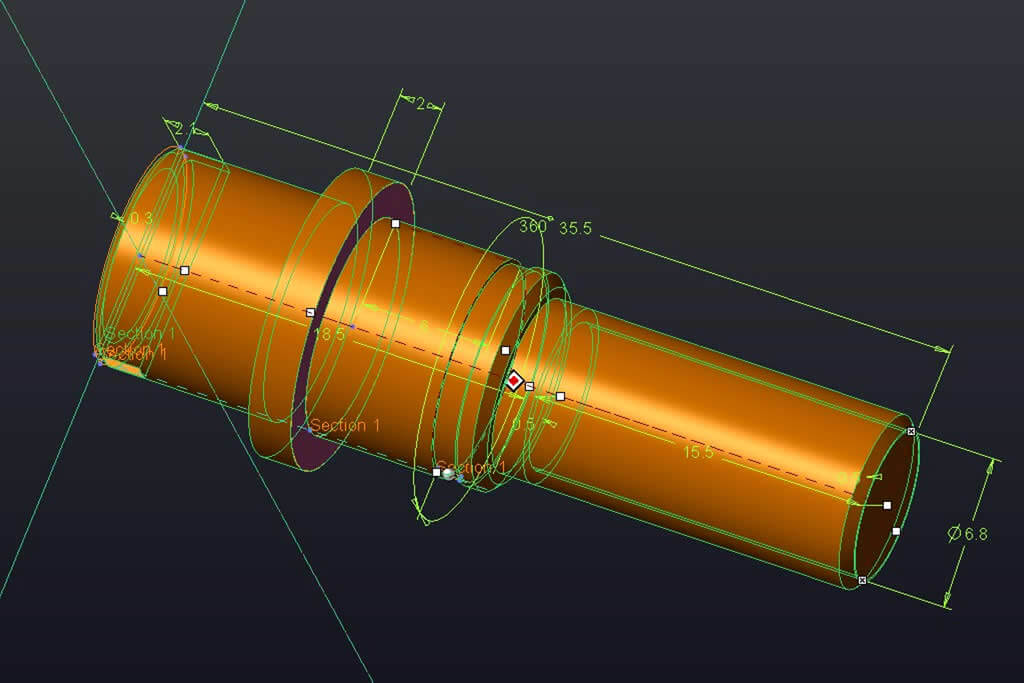

The first stage of producing your manufactured part is to create design drawings. Our toolmakers and designer engineers are able to present a service of managing the planning and completion of required CAD drawings.

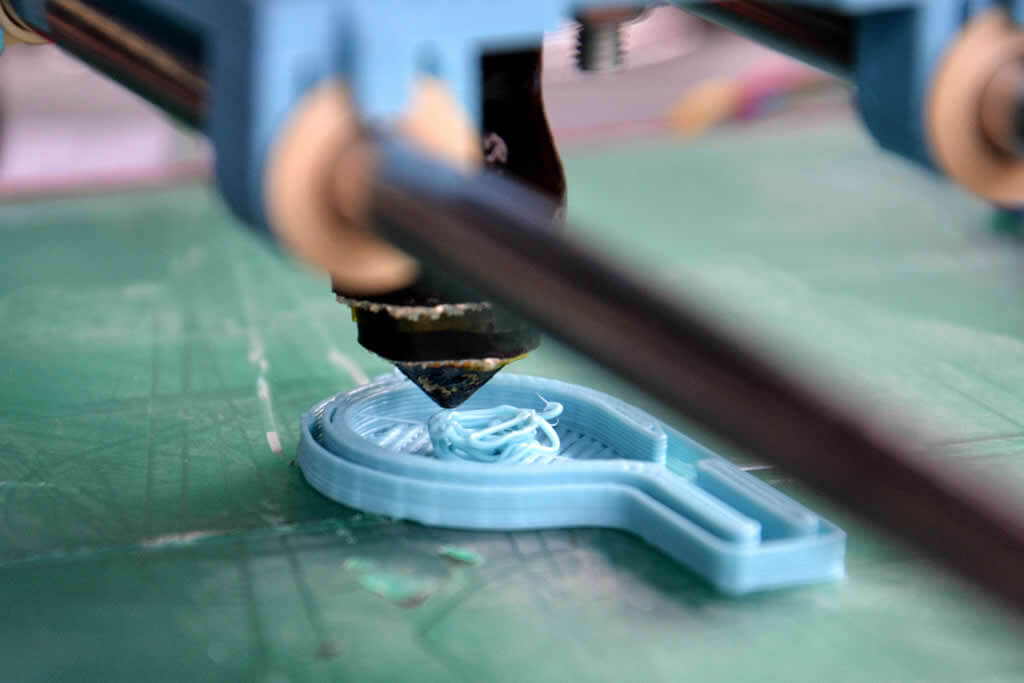

By use of our network of toolmakers and 3D printers we are able to oversee the planning and production of 3D printed prototype parts. The advantage of a working 3D prototype allows you to physically see the finished parts, this also allows for a range of testing platforms before investing in final tooling.

3D printing will produce a visual prototype illustrating geometry, size and any design features. This provides an invaluable insight highlighting any design issues or corrections which may need to be made before tool investment.

We strive to guarantee customer confidentiality and security is upheld to the highest standard in the manufacturing industry.